Berkshire East is a four-season mountain resort located in Western Massachusetts. This resort features skiing, snowboarding, mountain biking, camping, white water rafting, zip lines, and a mountain coaster. The resort needed to replace an existing septic system serving the main lodge of the mountain that was deemed a failure. Plans for future development of the property required a new system sized to handle larger future flows.

The project engineer, Matthew Puntin, P.E. of SK Design Group, considered several options for the 9,900 gallons per day (GPD) system including Infiltrator leachfield chambers and conventional stone and pipe. He ultimately selected an Advanced Enviro-Septic (AES) combined treatment and dispersal system because of the 25 percent footprint reduction as compared to chambers and the ability to install the system with the existing land contours. The footprint of a stone and pipe system would have had to be 50 percent larger than the selected AES system. In addition, the substantial reduction in footprint also reduced the construction cost.

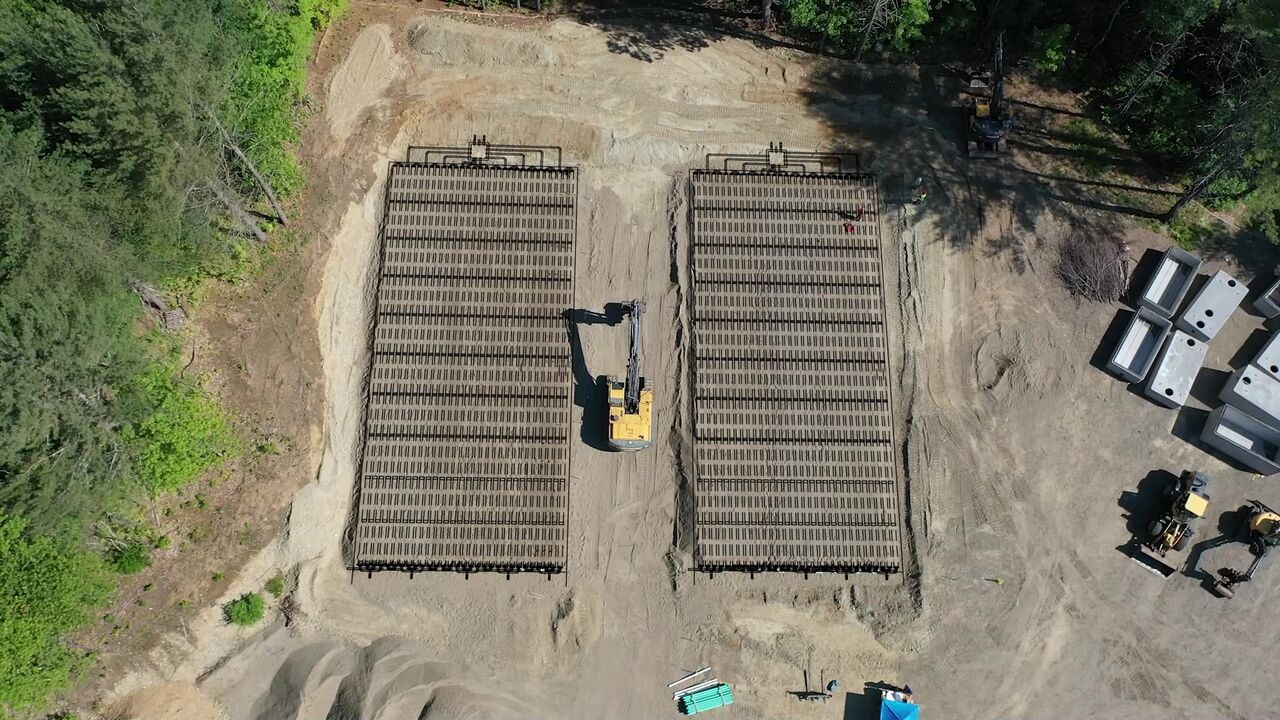

The 9,900 GPD AES system at Berkshire East includes 6,000 linear feet of AES pipe divided into two 5,000 GPD module beds. The total combined sand bed area for the system is 9,486 sq. ft. with a soil loading rate of 1.233 GPD/sq. ft. The AES subsurface combined treatment and dispersal system enabled the engineer and contractor to accommodate the cross-slope on the site by installing the AES in a stepped configuration to slope the system and reduce the amount of fill needed for the project