PRODUCTS USED

A small and steep city lot with no access to public sewer and water presented a challenge when a Minnesota home was sold and the new owner was faced with the need to replace an old, non-compliant single-family septic system.

The existing system consisted of an old concrete tank and a non-compliant drain tile. Site limitations included very steep slopes with retaining walls, permanent landscape features, and a soil horizon of 12-18-inches of silt loam over top of limestone bedrock. County code allowed for pre-treatment to reduce the vertical separation and overall footprint of the system.

Potential solutions for the 300 GPD system considered included connecting to city sewer and water, which was too expensive and installing a holding tank, which was also deemed not feasible for this full-time residence. Ultimately the system designer, Chris Priebe, designed a practical solution that would work for the homeowner and satisfy local regulators who originally thought that drainfield rock was the only solution for the dispersal bed.

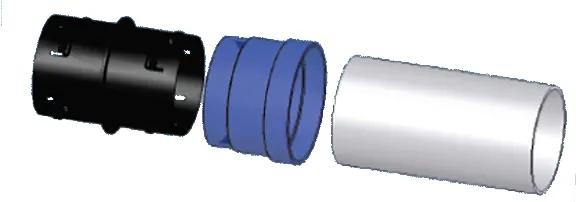

A Hoot H-600A with a 760 Salcor UV light was chosen for the pretreatment of the effluent. A 32-foot long by 12.5-foot wide absorption bed utilizing EZflow by Infiltrator geosynthetic aggregate bundles was selected for the pressurized at grade drainfield because of the ease of delivery and installation on this steep sloping site with limited access. A 2-inch PVC pressure pipe was placed in the upper tube of the EZflow modules.

The EZflow bundles were delivered to the site by the contractor and hand-carried up the hill to be placed on the prepared at-grade area. This eliminated the need for heavy equipment on the steep slopes that would have been necessary to carry rock up the hill and place it properly. The additional fill removed during the tank installation was used up hill from the at-grade treatment area to blend the system into the yard. Once completed, other than the inspection ports, the system was constructed to disappear into the landscape.