107B Railway Trench Installation Detail (PP)

Filename:

107B Railway Trench Installation Detail (PP).dwg

This document is the 107B Railway Trench Installation Detail (PP). Diagrams with descriptions and notes provided.

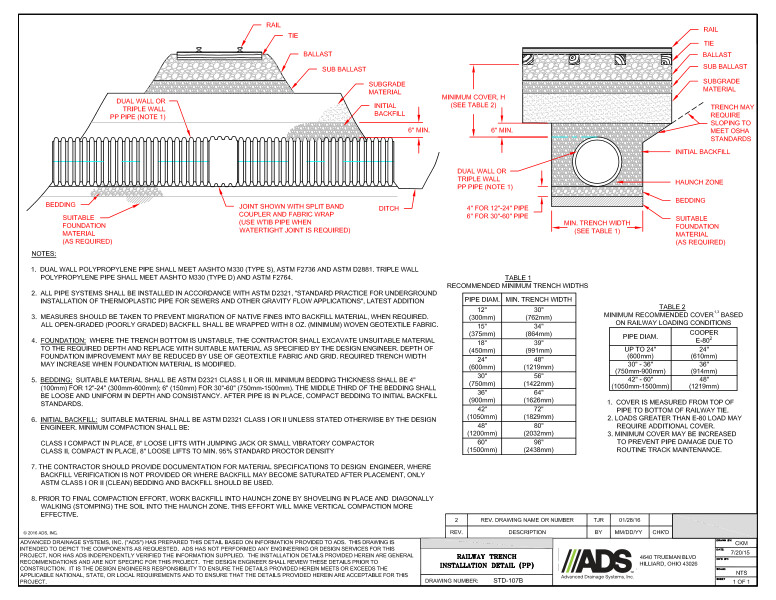

The first Railway Trench Installation Detail shows the rail, tie, ballast, sub-ballast, subgrade material, initial backfill, 6” minimum, ditch, dual wall or triple wall PP pipe, bedding, suitable foundation material and joint shown with split band coupler and fabric wrap (use WTIB pipe when watertight joint is required.

The second Railway Trench Installation Detail shows the rail, tie, ballast, sub-ballast, subgrade material, trench may require sloping to meet OSHA standards, initial backfill, haunch zone, 6” minimum, bedding, minimum cover/trench width and dual wall or triple wall PP pipe.

Table 1 for recommended minimum trench widths shows the measurements for various pipe diameters with minimum trench widths.

Table 2 for minimum recommended cover based on railway loading conditions shows the measurements for pipe diameter and Cooper E-80.

Notes state that dual wall polypropylene pipe shall meet AASHTO M330, ASTM F2736 and ASTM D2881. Triple wall polypropylene pipe shall meet AASHTO M330 and ASTM F2764. All pipe systems shall be installed in accordance with ASTM D2321. Measures should be taken to prevent migration of native fines into backfill materials. Foundation where the trench bottom is unstable, excavate unsuitable material to the required depth and replace with suitable material. Bedding with suitable material shall be ASTM D2321 Class I, II or III. Minimum bedding thickness shall be 4” and the middle 1/3 of the bedding shall be loose and uniform in depth and consistency. Initial backfill with suitable material shall be ASTM D2321, Class I or II. Contractor shall provide documentation for material and backfill verification. Prior to final compaction, work backfill into haunch zone by shoveling in place then stomping the soil into place.