PRODUCTS USED

- 360’ (110 m) of 24” (600 mm) HP Storm Dual Wall Pipe

- 760’ (232 m) of 30” (300-1500 mm) HP Storm Dual Wall Pipe

- 1,200 (366 m) of 36" (900 mm) HP Storm Dual Wall Pipe

- 480' (146 m) of 42" (1,050 mm) HP Storm Dual Wall Pipe

To better serve the growing Knoxville metropolitan area, the airport plans to do five major projects over the next five to six years.

The first of the projects was to rehabilitate and replace the airport’s taxiways, which serve the main runway 5R-23L. The taxiways had to be closed one at a time in order to not affect airplane traffic. As part of the rehabilitation, stormwater drainage pipe needed to be installed under the taxiways.

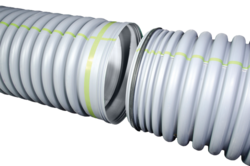

Advanced Drainage Systems, which has done numerous airport projects, worked with the engineer to allow HP Storm as an equal material to Class 3 RCP. Through discussions with the engineer, ADS communicated HP Storm is a proven product in this application with numerous installations, 100-year service life and structural capability to handle airport loading.

Since the taxiways would need to be closed, the installation needed to be done quickly to meet the tight timeline. ADS’ HP was chosen over RCP, since the HP Storm could be installed more quickly. HP Storm is manufactured in 20’ (6 m) sticks, while RCP is just 8’ (2.4 m). This allows for quicker installation and less joints in the run of pipe.

The contractor preferred to use HP Storm as it saved on cost, installed quickly and lowered the truckload count. Delivery trucks will be driving down runways and taxiways to deliver pipe to the staging area. The contractor had to be in contact with the control tower to determine when the trucks can drive on the taxiways and runways for deliveries.

HP Storm polypropylene pipe, which is approved by the Federal Aviation Authority (FAA), provides superior pipe stiffness, longer bells and spigots and a premium joint performance for a longer service life. The smooth interior wall offers additional strength and high flow capacity. HP Storm pipe meets or exceeds the standards specified in ASTM F2881 and AASHTO M330 and the extended bell and spigot meets ASTM D3212. Polypropylene is resistant to the effects of chemicals, abrasion, hot soils and effluent.