PRODUCTS USED

- 23,000’ (7,010 m) of 15”-60” (375-1500 mm) HP Storm Dual Wall Pipe

But at this warehouse, not only was water quality important, so was the discharged water temperature.

Frederick, Seibert and Associates, Inc. (FSA) (Hagerstown, MD) created an underground system with an 800,000-gallon capacity using large diameter thermoplastic pipe that would hold and cool the water. This enables the water to flow at a controlled rate into nearby Antietam Creek without raising the water temperature to help protect the creek’s fish.

“The Currwood site is bordered by the Antietam Creek,” said Trevor M. Frederick, P.E., vice president, FSA. “It’s a put-and-take trout stream within Washington County. The Maryland Department of Environment wanted us to find a way to control the water temperature for the release of the stormwater. An underground pipe system would allow the water to stay cooler than what it would’ve been in an above-ground system.”

The city’s Stormwater Management Program seeks to not only limit flooding and runoff-related damage, but also to improve the quality of the water in the Chesapeake Bay, the Potomac River and all tributary streams in Washington County. The city’s Stormwater Management Ordinance establishes the stormwater quality and quantity requirements for both new developments, as well as previously constructed sites that are being redeveloped. The city also developed a program to comply with its National Pollutant Discharge Elimination System Permit issued by the Environmental Protection Agency.

The Currwood Logistics Park has two buildings with nearly two million square feet of industrial and warehouse space plus offices on a 134-acre site. The underground stormwater management system has two separate units, both constructed using 60” HP Storm. Detention Unit #1 with a capacity of 46,435 cubic feet used 2,460’ of the pipe in a 60’ x 350’ x 7’ pit, while Detention Unit #2 with a capacity of 61,245 cubic feet used 3,160 feet in a 60 x 450 x 7’ pit. A parking area for trucks is on top of the units. More than 17,000’ of HP Storm in diameters ranging from 15”- 48” were used for connections and to carry runoff.

“We did as many ponds as we could on the property, but there were a number of restrictive easements, flood plains, forest easements, utility easements, that prohibited us from putting everything above ground,” said Frederick. “That’s why we wanted these underground systems to retain and slowly release the storm water. We had to look at temperature control and how the underground pipe system would allow the water to stay cooler than what it would’ve been in an above-ground system. The allowable water temp discharging to the creek is 75˚F.”

Unit One has a 10-year inflow of 30.18 cfs and a 10-year outflow of 6.03 cfs, controlled by a Weir wall within an outlet box with a 4” low flow orifice. Unit Two has 10- year inflow rate of 40.61 cfs and a 10-year outflow of 9.25 cfs, controlled by a Weir wall in an outlet box with a 5” low flow orifice.

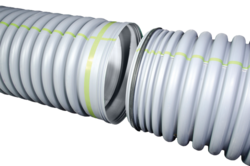

A high-performance polypropylene (PP) pipe for gravity-flow storm drainage applications, HP Storm pipe provides stiffness and premium joint performance. The ADS design couples advanced polypropylene resin technology with a proven, dual-wall profile design for superior performance and durability. The pipe is corrosion resistant and is unaffected by salts, chemicals and hot soils. According to the company, burial cover can range from 1’-44’, depending on the pipe’s diameter.

HP Storm meets or exceeds ASTM F2881 and AASHTO M330 and is approved by the Army Corps of Engineers for storm drainage applications under Section 33 40 00 (Unified Facilities Guide Specifications). The ADS pipe comes in 20’ lengths that reduces the number of joints. The longer length and lower weight of the thermoplastic pipe means installation is easier and faster and provides a favorable installed cost with an established RSMeans installation rate of 200’ a day. Soil at the Currwood site was mostly clay with block pinnacles. Drilling and blasting were required to remove the subgrade. Cover depth ranged from 7-10’.

“We chose to go with the ADS pipe product because we have used it on previous projects,” Frederick said, “We were comfortable with the results we received on those (previous) projects.