PRODUCTS USED

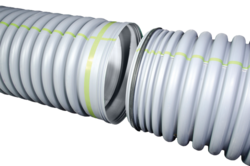

- 440’ (134 m) of 18” (450 mm) HP Storm Dual Wall Pipe

The City of Solana Beach had corrugated metal pipe (CMP) failing in various sites across the city due to the harsh conditions of corrosive soils and saltwater in the area. With the storm drains failing, the city needed to come up with an alternative pipe for its storm drain maintenance.

Solana Beach wanted a pipe material with a longer service life that maintains its structural integrity when exposed to harsh chemicals commonly found in effluent. Caltrans Highway Design Manual notes that polypropylene exhibits good abrasion resistances and is virtually corrosion free (Section 852.6 Plastic Pipe). Advanced Drainage Systems’ HP Storm has a 100-year service life and provided the needed pipe strength and minimum cover requirement of 1’ (0.3 m).

The city considered using high-density polyethylene pipe with a steel iron plate for strength and durability because of the shallow cover. ADS representatives worked with Solana Beach’s engineers, who were unaware of ADS’ HP Storm, to showcase the benefits of the polypropylene pipe in a shallow burial storm drain application.

Polypropylene pipe is included in key regional standards, including the Greenbook and Caltrans Standard Specifications, Section 64-2. ADS products are a trusted choice for stormwater management with a proven track record of reliability.

Besides the shallow burial depth, the city was impressed that the pipe was readily available to ship. HP Storm connects to any pipe material and drainage structures using a Marmac ® coupler. Cutting plastic pipe in the field is not labor intensive, limits harmful chemical inhalation and allows for quick installation, which reopens roadways faster to the public. The lightweight properties of polypropylene creates easier and faster installations that deliver increased safety for workers.

City of Solana Beach had specified HDPE but ADS representatives were able to provide the value proposition of HP Storm, which the owner agreed to specify due to HP Storms superior performance, design life, and inert material.

The contractor, Bert W. Salas, Inc., had installed HP Storm previously and was pleased to utilize the pipe. “Our team has used ADS HP Storm polypropylene pipe on multiple projects and have had a great experience with the installation and performance of the pipe,” said Robert Salaz of Bert W. Salas, Inc. “Beyond the cost saving, the pipe’s inline bell and watertight double gasket provide a great joint for storm drain applications. In the Solana Beach install, we needed a product that could handle a shallow burial without a metal plate over the top, and polypropylene easily met the specification.”

HP Storm polypropylene pipe provides superior pipe stiffness, longer bells and spigots and a premium joint performance. ADS offers a watertight and air-testable joint, which is the most common location for repairs and maintenance. Longer stick length reduces the number of joints in a drainage system, therefore reducing the risk potential and extending service of life. In this case, HP Storm was utilized in a shallow burial depth, but it can be installed up to 40’ (12 m) deep in certain diameters due to its pipe stiffness. The smooth interior wall offers additional strength and high flow capacity. HP Storm pipe meets or exceeds the standards specified in ASTM F2881 and AASHTO M330 and the extended bell and spigot meets ASTM D3212. Polypropylene is resistant to the effects of chemicals, abrasion, hot soils and effluent.