TN 5.08 Laser Profiling of Flexible Pipe

Filename:

TN 5.08 Laser Profiling of Flexible Pipe.pdf

This document is the TN 5.08 Laser Profiling of Flexible Pipe. Profiling description, position & orientation tracking and pipe conditions explained.

Historically, the use of closed-circuit television (CCTV) inspection technologies has been a common method to provide post installation inspection of various pipe types. This technology can provide a qualitative analysis of the interior of a pipeline, but it can be limited due to the subjective nature of the visual assessment process. Laser profiling, which was originally developed for the thermoplastic Cured in Place Pipe industry, is a new technology that can provide precise measurements of pipe parameters.

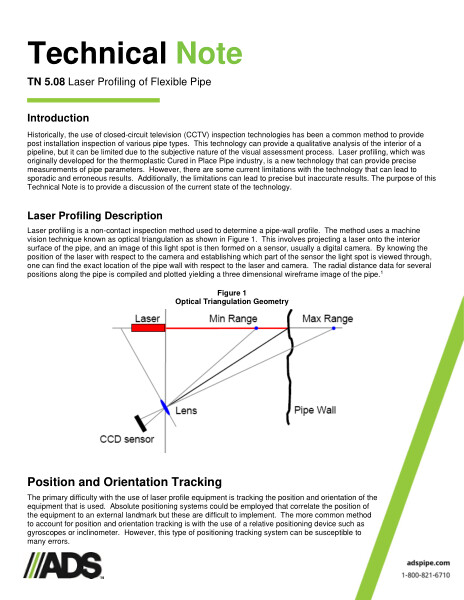

The purpose of this Technical Note is to provide a discussion of the current state of the technology. Laser profiling is a non-contact inspection method used to determine a pipe-wall profile. The method uses a machine vision technique known as optical triangulation. A figure shows the Optical Triangulation Geometry.

The primary difficulty with the use of laser profile equipment is tracking the position and orientation of the equipment that is used. Absolute positioning systems could be employed that correlate the position of the equipment to an external landmark but these are difficult to implement. The more common method to account for position and orientation tracking is with the use of a relative positioning device such as gyroscopes or inclinometer.

In addition to bumps or offsets, the presence of sediment, water and/or other debris can create vertical inconsistencies resulting in a pipe profile illusion inconsistent with the actual pipe profile condition. For the best results, the pipe should be clear of all sediment, debris and water. Otherwise, considerable post-inspection data analysis will be necessary to distinguish whether deflection readings were actual or a false positive created non ideal pipe conditions.

Environmental factors relating to fog or dew formation in the pipeline, test pipe free of these conditions. For calibration, calibrate under controlled conditions. Equipment limitations varies with manufacturers. Have the laser and camera on the same frame to fix the location to eliminate rational errors. Data analysis of laser profiling systems can take up to 2 weeks to complete and needs to be evaluated and compared against the overall project schedule.