N-12 Flex Pipe Installation Guide

Filename:

N-12 Flex Pipe Installation Guide.pdf

The ADS® N-12® Flex Pipe Agricultural Installation Guide offers recommendations for dependable installation. Be sure to follow proper design criteria for drainage systems available from ASTM F449 and ADS. Proper backfill materials and placement procedures are recommended for long-term drainage system performance. Poor soils and high loads may affect how the drainage system performs.

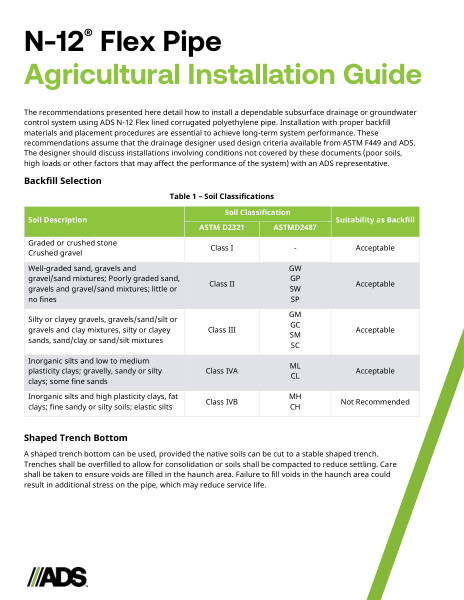

Backfill selection guidelines are offered in Table 1, Soil Classifications, for the ADS N-12 Flex Pipe. Many backfill materials are suitable, such as ASTM D2321, Class I, graded or crushed stone or crushed gravel. Do not use inorganic silts and high plasticity clays, fat clays; fine sandy or silty soils; elastic silts as classified in ASTM D2321, Class IVB, and ASTMD2487, ML & CH.

Shaped trench bottoms are acceptable, provided the native soils can be cut to a stable shaped trench. Trenches need to be overfilled to allow for consolidation, or soils should be compacted to reduce settling. Be sure to fill voids in the haunch area. Failure to fill voids in the haunch area could result in additional stress on the pipe, which may reduce service life.

Boot design for a N-12 Flex Pipe installation has key components to consider, such as boot width, cutting plate width, bend radius and boot shape. To reduce the friction and force exerted on the pipe during installation, the inside width of the boot should be about 3” (75 mm) wider than the outside diameter (OD) of the pipe. Do not use the same boot width for all pipe diameters. The boot’s recommended minimum bend radius is 50” (1250 mm), but a boot with a larger bend radius is acceptable. See the “Boot Design” section for more information.

Installation recommendations include maximum burial depth of plastic pipe. For plow installations, the recommended maximum cover height for N-12 Flex is 8’ (2.4 m), which is measured from top of pipe to final grade. Deeper burial depths may be achieved by changing the trench shape, installation method, backfill material, compaction of backfill material or combinations thereof. See ADS Installation Guide 1.03 “Agricultural Installation for N-12 Pipe” for guidance on other trench construction methods and corresponding maximum cover height recommendations. Do not stretch the pipe during installation. Stretching of the pipe could lead to excessive deflection or buckling of the pipe. Where couplers are used, use additional tape so the pipe coils do not separate during installation.