TN 4.01 Chemical Resistance of Polyethylene and Elastomers

Filename:

TN 4.01 Chemical Resistance of Polyethylene and Elastomers.pdf

This document is the TN 4.01 Chemical Resistance of Polypropylene and Elastomers. Test procedures for Polypropylene and Elastomers supported by tables.

The results are of testing performed on HDPE material, compiled from multiple sources. In evaluating the capability of polyethylene pipe, fittings and manholes to withstand chemical attack, consideration should be given to the following: The effect of an active substance on polyethylene is not as severe when contact is intermittent. Increasing temperature increases chemical activity. Internal pressure may affect the rate of penetration of a substance. Excessive bending and other stresses resulting from improper installation may affect the life of polyethylene products.

An example would be circumferential deflection beyond 50% or placing pipe directly on a large, sharp rock.

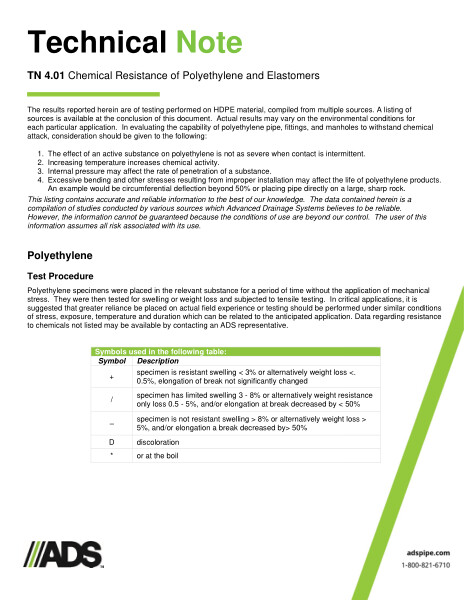

Polypropylene specimens were placed in the relevant substance for a period of time without the application of mechanical stress. They were then tested for swelling or weight loss and subjected to tensile testing. The supporting table details the substance, Polypropylene concentration, 68 F and 140 F values.

The criteria for the ratings of various elastomers presented here (Natural Rubber, SBR, and EPDM) were primarily volume swell resistance, compression set resistance, and aging resistance. The supporting table for Elastomers details the substance, Natural Rubber, Styrene Butadiene and Ethylene Propylene values.