TN 5.15 Integral Bell Transition for HP Pipe

Filename:

TN 5.15 Integral Bell Transition for HP Pipe.pdf

This document is the TN 5.15 Integral Bell Transition for HP Pipe. Connections and vent tube sealings explained. Photographs and diagrams are included.

ADS offers a variety of joints to the marketplace. HP pipe products are manufactured using polypropylene resin and is available in 12” through 60” with exterior corrugations (dual wall), while 30” through 60” may also be available with an exterior shell (triple wall). The HP products are also available for storm and sanitary sewer markets. While HP pipe can be cut in the field, the connection method must be based on the allowable joint performance for the project.

ADS HP pipe products have an integral bell which maintains a constant pipe outside diameter (OD). This constant OD eliminates the need for bell holes and makes it easier to maintain line and grade during installation. The bell and spigot design for HP products, with an elastomeric rubber gasket meeting ASTM F477, meets or exceeds the watertight testing requirements outlined in ASTM D 3212.

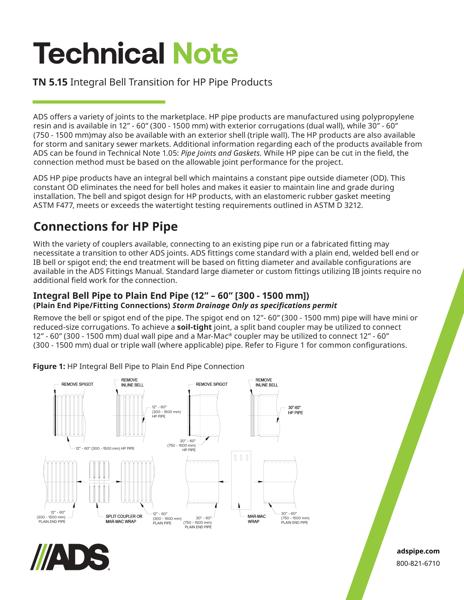

With the variety of couplers available, connecting to an existing pipe run or a fabricated fitting may necessitate a transition to other ADS joints. ADS fittings come standard with a plain end, welded bell end or IB bell or spigot end; the end treatment will be based on fitting diameter and available configurations.

Connections discussed are the Integral Bell Pipe to Plain End Pipe where a split band coupler is utilized for a soil-tight joint. A figure of the connection is shown. Integral Bell Pipe to a Welded Bell to connect dual wall pipe or dual wall fittings. Photographs show the connection. Integral Bell Pipe to Bell-Bell Coupler Connection for field modifications. A figure is provided.

Vent Tube Sealing is the manufacturing process of corrugated plastic pipe requires the release of hot air from inside the corrugations in order to properly form the corrugations. This hot air is allowed to escape from the corrugations during the extrusion process via vent tubes that run the length of the pipe. Vent tubes become exposed when the pipe is cut in the field to install a fitting, connect to a manhole, or otherwise adjust the length of a pipe run. Exposed vent tubes may result in a leak path, and therefore is recommended that they be sealed. It is important that these vent tubes, when present, be sealed whenever the pipe is cut in the field.