Citi Field (New York, NY) Case Study

Filename:

Citi Field (New York, NY) Case Study.pdf

This document is the case study for the Citi Field, New York, NY. A new athletic playing field installation using ADS HDPE drainage system is discussed.

Citi Field stadium has a state-of-the-art playing field that floats - requiring the drainage system to move with the field. The stadium is built on a swamp filled with ash and a high water table. Citi Field was built for the field to float independent of the stadium to allow for future settling. Therefore, ADS HDPE pipe was selected for the drainage system due to its ability to flex and maintain joint integrity during the settling. ADS pipe also would maintain its gradient for water flow by moving with the field’s settling.

A 430’ (131 m) of N-12 watertight pipe runs from behind home plate to the center field warning track to create a trunk line. Connected to the trunk line are 6” (150 mm) lateral branches – 42 on each side of the trunk with 10’ (3 m) spacing. The 6” pipe is perforated to allow for drainage and allow air to be pumped into the pipe to aid in the natural grass turf’s growth. Warm air is used during cool weather to kick start the growth of the turf in the spring, prior to the season’s beginning.

The installation was done in 2006-09 using 11,600 (3,535 m) of 6” (150 mm) of N-12® pipe, 560’ (170 m) of 6” (150 mm) N-12 perforated pipe, 240’ (73 m) of 6” (150 mm) N-12 solid pipe, 4 oz. woven geotextile.

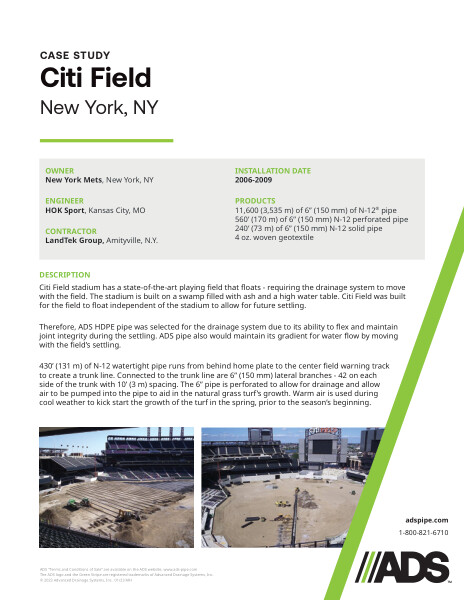

Photographs of the project are included.