CSO Separation Pipeline (Lewiston, ME) Case Study

Filename:

CSO Separation Pipeline (Lewiston, ME) Case Study.pdf

This document is the case study for CSO Separation Pipeline. When completing a sewer overflow, a rock ledge led to switching to SaniTite HP Pipe.

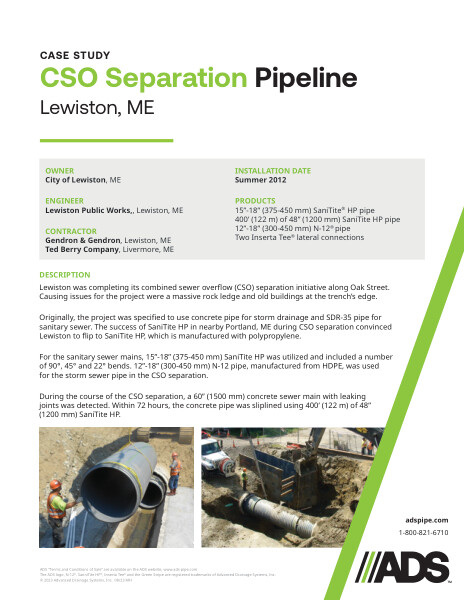

Lewiston was completing its combined sewer overflow (CSO) separation initiative along Oak Street. Causing issues for the project were a massive rock ledge and old buildings at the trench’s edge.

Originally, the project was specified to use concrete pipe for storm drainage and SDR-35 pipe for sanitary sewer. The success of SaniTite HP in nearby Portland, ME during CSO separation convinced Lewiston to flip to SaniTite HP, which is manufactured with polypropylene.

For the sanitary sewer mains, 15”-18” (375-450 mm) SaniTite HP was utilized and included a number of 90°, 45° and 22° bends. 12”-18” (300-450 mm) N-12 pipe, manufactured from HDPE, was used for the storm sewer pipe in the CSO separation.

During the course of the CSO separation, a 60” (1500 mm) concrete sewer main with leaking joints was detected. Within 72 hours, the concrete pipe was sliplined using 400’ (122 m) of 48” (1200 mm) SaniTite HP.

The installation was done in summer of 2012 using 15”-18” (375-450 mm) SaniTite® HP pipe, 400’ (11,491 m) of 48” (1200 mm) SaniTite HP pipe, 12”-18” (300-450 mm) N-12® pipe and two Inserta Tee® lateral connections.

Photographs of the project are included.