TN 5.16 Methods for Sealing Vent Tubes

Filename:

TN 5.16 Methods for Sealing Vent Tubes.pdf

This document is the TN 5.16 Methods for Sealing Vent Tubes. An explanation of the vent tubes method is supported by a vent plug kit table.

The manufacturing process of corrugated plastic pipe requires the release of hot air from inside the corrugations in order to properly form the corrugations. This hot air is allowed to escape during the extrusion process via vent tubes that run the length of the pipe. Vent tubes become exposed when the pipe is cut in the field to install a fitting, connect to a manhole, or otherwise adjust the length of a pipe run. Exposed vent tubes may result in a leak path, and therefore they be sealed. It should be noted that internal cuts or exposed vent tubes are not structural concerns and the requirement to seal them depends on site conditions and project specifications. A variety of methods can be used to seal vent tubes.

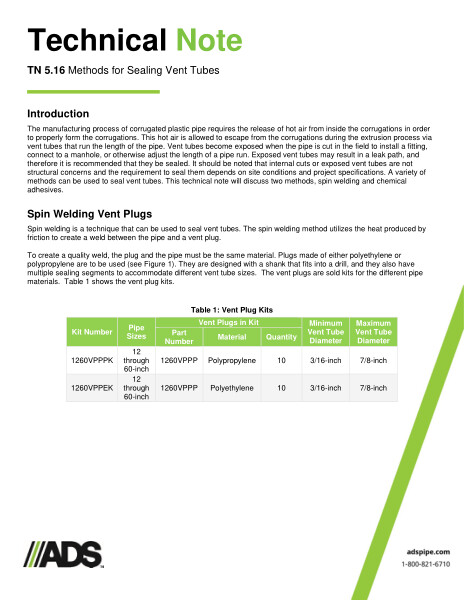

Spin welding is a technique that can be used to seal vent tubes. The spin welding method utilizes the heat produced by friction to create a weld between the pipe and a vent plug. To create a quality weld, the plug and the pipe must be the same material. Plugs made of either polyethylene or polypropylene are to be used. They are designed with a shank that fits into a drill, and they also have multiple sealing segments to accommodate different vent tube sizes. The vent plugs are sold kits for the different pipe materials.

A table for Vent Plug Kits is provided.

Installation needs tools that are a standard drill and drill bit. The drill should be set to its highest speed and it must be able to reach a minimum of 1500rpm. If using a cordless drill, it should have a fully charged battery. A drill bit will only be necessary in a case where the vent tube diameter is smaller than the minimum diameter. If the vent tube diameter is too small, it will need to be drilled to the correct size. 13 steps are listed for installation instructions with photographs.

Another method of sealing vent tubes is by using a chemical adhesive along with polyolefin material. This approach requires a specially designed 2-part adhesive, applicator gun and polyolefin material in the shape of small discs. This method can be more cumbersome and expensive than the aforementioned procedure, but may be used when spin welding is no longer an option, as may be the case with a very large vent tube. 5 steps to take are included with photographs.