Seattle-Tacoma International Airport (SeaTac, WA) Case Study

Filename:

Seattle-Tacoma International Airport (SeaTac, WA) Case Study.pdf

This document is the case study for the Seattle-Tacoma International Airport. By utilizing SaniTite HP pipe, the airport updated its storm water drainage system.

In the summer of 2015, while rebuilding the 46-year-old center runway at Seattle-Tacoma International Airport (Sea-Tac), the Port of Seattle chose to upgrade the storm water drainage system. A variety of overlapping requirements needed to be met when upgrading the storm water drainage system.

The system had to assure zero ponding within the runway safety area, zero pipe failures, rapid pipe installation, meet Federal Aviation Authority (FAA) grant eligibility requirements and have a structurally-robust pipe. By utilizing SaniTite HP pipe, Sea-Tac could meet all of the above requirements. The upgrade was tightly scheduled as completion was needed in 180 days without shutting down the runway. By using SaniTite HP in 20’ (6 m) lengths, the Port of Seattle saved time on installation as

compared to RCP pipe and would have less joints along the entire system. In order to increase the efficiency of draining the field over 8,640’ (2,633 m) of perforated N-12 pipe was installed around the perimeter.

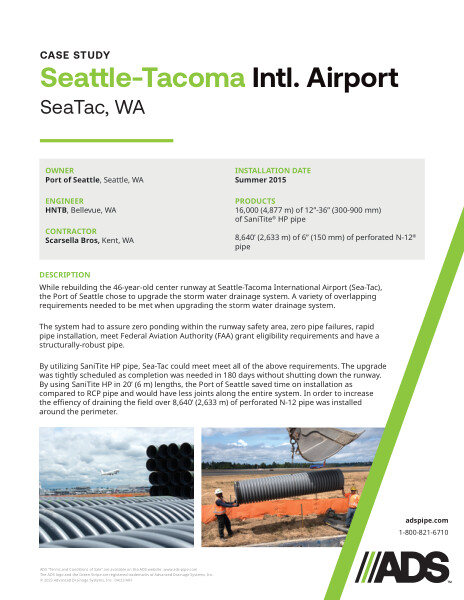

Photographs of the pipe installation are included.