Runway Drainage Pipe Sliplined (South Haven, MI) Case Study

Filename:

Runway Drainage Pipe Sliplined (South Haven, MI) Case Study.pdf

This document is the case study for the Runway Drainage Pipe Slipline. A drainage ditch under the South Haven Airport runway was replaced with SaniTite HP.

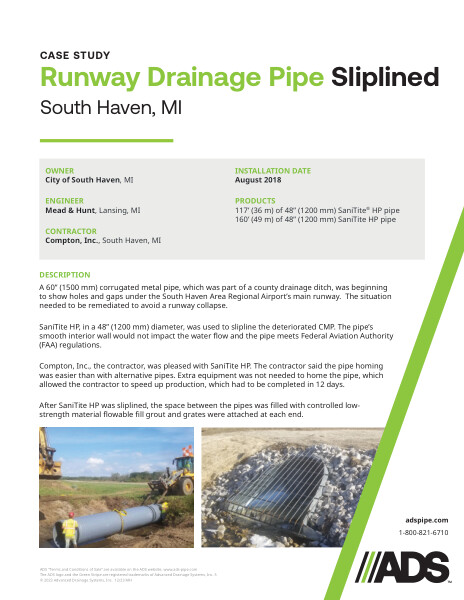

A 60” (1500 mm) corrugated metal pipe, which was part of a county drainage ditch, was beginning to show holes and gaps under the South Haven Area Regional Airport’s main runway. The situation needed to be remediated to avoid a runway collapse.

SaniTite HP, in a 48” (1200 mm) diameter, was used to slipline the deteriorated CMP. The pipe’s smooth interior wall would not impact the water flow and the pipe meets Federal Aviation Authority (FAA) regulations.

Compton, Inc., the contractor, was pleased with SaniTite HP. The contractor said the pipe homing was easier than with alternative pipes. Extra equipment was not needed to home the pipe, which allowed the contractor to speed up production, which had to be completed in 12 days. After SaniTite HP was sliplined, the space between the pipes was filled with controlled low-strength material flowable fill grout and grates were attached at each end.

The installation was done in August 2018 using 117’ (36 m) of 48” (1200 mm) SaniTite® HP pipe and 160’ (49 m) of 48” (1200 mm) SaniTite HP pipe.

Photographs of the project are included.