Culvert Repair (Durham, NH) Case Study

Filename:

Culvert Repair (Durham, NH) Case Study.pdf

This document is the case study for the Durham NH SaniTite HP Slipline. Repair of a storm water culvert using SaniTite HP pipe discussed.

ADS SaniTite HP pipe was the definite product of choice to repair a storm water culvert. The 99-year-old poured-in-place box culvert runs under a railroad through a brownfield site. The culvert repairs had to withstand contamination from above, allow free flow of the creek and withstand 17’ (5 m) of earth weight and railcars passing overhead.

With these circumstances, the pipe required at least a 46 psi (317 kPa) pipe stiffness, joint pressure rating of 15 psi (103 kPa) and an E80 railroad load - all of which SaniTite HP met. The initial costs were $180,000, but nearly $80,000 was saved by utilizing SaniTite HP. SaniTite HP chosen because of its material, economical price and a standard contractor could easily and quickly install it. In fact, the pipe system of 200 feet was put together by a crew of four in about two hours.

The installation was done in Summer 2011 using 200’ (60 m) of 60” (1500 mm) SaniTite HP pipe.

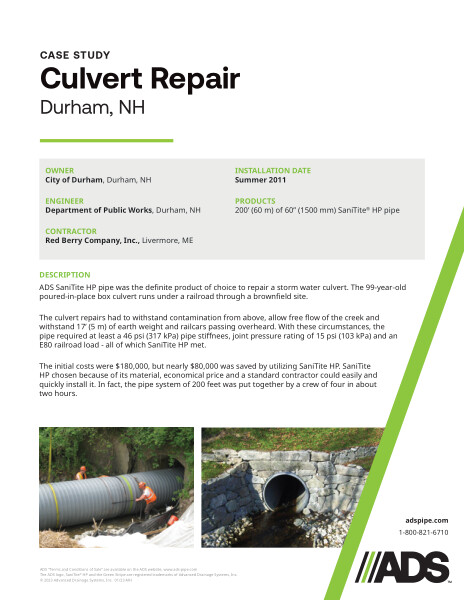

Photographs of the project are included.